Tag Archives: fabric

Next page →

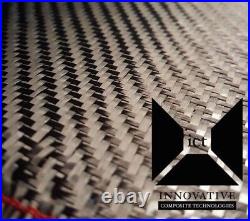

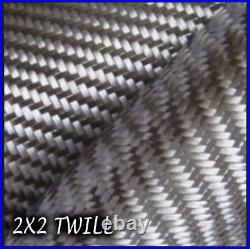

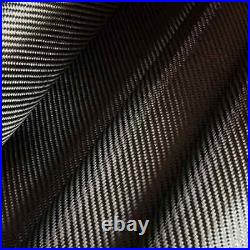

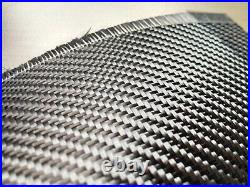

3 yards Carbon Fiber Fabric Cloth 2×2 Twill Weave (3k, 6oz, 50 x 108)

Twill weave carbon fiber cloth is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality. It has both formability and stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows. Carbon fiber is preferred as it has the highest tensile strength of all reinforcing materials. The dry 3K 2×2 Twill Weave Fabric gives the classic carbon fiber look and conforms to complex parts better than plain weave. It boasts a combined strength and stiffness-to-weight that is unmatched in the composites industry. In fact, when looking at strength to weight comparisons, carbon fiber outperforms most traditional building materials. Carbon fiber can be found everywhere from auto racing to aerospace. Its unmatched strength and weight, along with its modern cosmetics, have made it a widespread favorite in today’s composite industry. Highly desirable for modern composite parts in the aerospace, auto, marine, and sporting goods industries. This is a first quality commercial grade 3K carbon fiber fabric and is made in the USA. 3K means each tow/bundle is constructed of 3000 filaments. The bundles are woven together to form the fabric, which makes it a strong, yet lightweight material. 3K, 563ksi, 34msi, 1.7% elongation. 6 ounces per square yard. When purchasing multiple quantities of the same fabric you will receive one continuous length of that material.

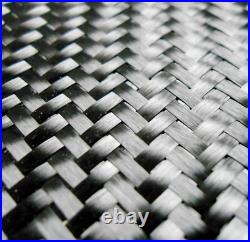

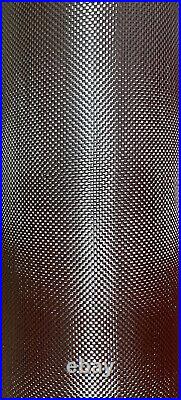

10 Yards Carbon Fiber Fabric Cloth 8 Harness Satin 60 Twill Plain Weave SALE

Up for sale are 10 yard lengths of a 60 minimum width new carbon fiber fabric woven in a 8 Harness Satin weave pattern. This material is made with 3k fiber and is approx. Material may have fine tracer yarns in it and is a great material for bulking and or backup of parts. It also can be used for cosmetic parts but it would be best suited for building up parts. I have about 1000 yards of various 5HS, 4HS, Plain Weave and 4×4 Twill pattern fabrics I have bought to build race car parts with and cleaning out the remaining inventory I have in 25 yard sections. There is a small chance your order may be split into two pieces. Once I run out of one roll I will continue onto the next. The master rolls I have range from 50-150 yards. It is too complicated to list everything by every width so just trying to sell it reasonable and make it easy for everyone. Please check my other listings if you need the 4 or 5 Harness, 2×2 Twill, plain weave or 4×4 twill. If you have other questions please let me know. We are located in WI, so most areas of the country are no more than 5 days away. Please take the extra second to add a NON-RESIDENTIAL ADDRESS to your account or when checking out. If you check out with a Residential Address, this may add significant time to completing your order.

8 yards 50 Carbon Fiber Fabric Cloth 2×2 Twill Weave (3k, 6oz, 50 x 288)

Twill weave carbon fiber cloth is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality. It has both formability and stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows. Carbon fiber is preferred as it has the highest tensile strength of all reinforcing materials. The dry 3K 2×2 Twill Weave Fabric gives the classic carbon fiber look and conforms to complex parts better than plain weave. It boasts a combined strength and stiffness-to-weight that is unmatched in the composites industry. In fact, when looking at strength to weight comparisons, carbon fiber outperforms most traditional building materials. Carbon fiber can be found everywhere from auto racing to aerospace. Its unmatched strength and weight, along with its modern cosmetics, have made it a widespread favorite in today’s composite industry. Highly desirable for modern composite parts in the aerospace, auto, marine, and sporting goods industries. This is a first quality commercial grade 3K carbon fiber fabric and is made in the USA. 3K means each tow/bundle is constructed of 3000 filaments. The bundles are woven together to form the fabric, which makes it a strong, yet lightweight material. 3K, 563ksi, 34msi, 1.7% elongation. 6 ounces per square yard. When purchasing multiple quantities of the same fabric you will receive one continuous length of that material.

10 yards 50 Carbon Fiber Fabric Cloth 2×2 Twill Weave (3k, 6oz, 50 x 360)

Twill weave carbon fiber cloth is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality. It has both formability and stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows. Carbon fiber is preferred as it has the highest tensile strength of all reinforcing materials. The dry 3K 2×2 Twill Weave Fabric gives the classic carbon fiber look and conforms to complex parts better than plain weave. It boasts a combined strength and stiffness-to-weight that is unmatched in the composites industry. In fact, when looking at strength to weight comparisons, carbon fiber outperforms most traditional building materials. Carbon fiber can be found everywhere from auto racing to aerospace. Its unmatched strength and weight, along with its modern cosmetics, have made it a widespread favorite in today’s composite industry. Highly desirable for modern composite parts in the aerospace, auto, marine, and sporting goods industries. This is a first quality commercial grade 3K carbon fiber fabric and is made in the USA. 3K means each tow/bundle is constructed of 3000 filaments. The bundles are woven together to form the fabric, which makes it a strong, yet lightweight material. 3K, 563ksi, 34msi, 1.7% elongation. 6 ounces per square yard. When purchasing multiple quantities of the same fabric you will receive one continuous length of that material.

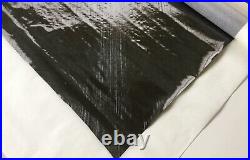

CarbonX Lightweight 30gsm Bi-layer Spread Tow Carbon Fabric (-45/+45, type B) USA

Premium intermedium modulus high strength CarbonX Ultralight 30gsm Non Woven Spread Tow Carbon Fabric (-45/+45, type B). Size: 10ft x2ft (310cm x 61cm). Dry bixial spread carbon fiber fabric. Fiber type: Intermediate Modulus Carbon Fiber. Tensile Strength: 5800 MPa. Density: 1.78 g/cm3. Filament diameter: 5.2? M. Direction of layers: -45;+45 type B. Resin consumption: 40 g/m², laminate thickness: 0.050 mm, laminate weight: 70 g/m². Competitive RC airplane (F3K, F3J, F3F, F5j, etc), UAV, motor sports, marine construction, sports equipment and model construction. This biaxial NCF (non wowen carbon fiber) has 2 unidirectional plies laid at an angle of ± 45° which are bonded with an epoxy-compatible binder to each other. Drapability is improved compared to conventional NCF with plastic-scrim. Due to marginal ondulation there is a better utilisation of the fibre’s properties. Particular advantage: torsional layers could be done without offcut. Condition is Brand New.

10 Yards Carbon Fiber Fabric Cloth 6k 370gsm 50 2×2 Twill Weave SALE

Up for sale are 10 yard lengths of a 50 new carbon fiber fabric woven in a 2×2 Twill Weave pattern. This material is made with 6k fiber and is approx. Material is a great material for bulking and or backup of parts. It also can be used for cosmetic parts but it would be best suited for building up parts. I have about 1000 yards of various 4HS, Plain Weave and 4×4 Twill pattern fabrics I have bought to build race car parts with and cleaning out the remaining inventory I have in 50 yard sections. There is a small chance your order may be split into two pieces. Once I run out of one roll I will continue onto the next. The master rolls I have range from 50-150 yards. It is too complicated to list everything by every width so just trying to sell it reasonable and make it easy for everyone. Please check my other listings if you need the plain weave, 4×4 or 4HS. If you have other questions please let me know. We are located in WI, so most areas of the country are no more than 5 days away. Please take the extra second to add a NON-RESIDENTIAL ADDRESS to your account or when checking out. If you check out with a Residential Address, this may add significant time to completing your order.

Fabric Saddle Scoop Ultimate Carbon Flat Blk/Silver 142mm New

SOUTHERN CALIFORNIA’S PREMIER CYCLING BOUTIQUE. CUSTOM BUILDS. PARTS. SERVICE. CYCLING CULTURE. WE’RE CANNONDALE, ROCKSHOX, AND SRAM EXPERTS. The multiple award winning Scoop saddle from Fabric. Suitable for all types of cycling. The Radius profile suits an upright riding position. Our Scoop saddle replaces a hard, stretched cover with a unique, three-piece construction that builds in comfort. Available in three profiles, with three rail options, a choice of carbon or nylon base. Carbon rail / Carbon base / 180g. W: 142mm L: 282mm. Performance and comfort are not mutually exclusive. The Flat profile offers the best of all worlds, making it ideal for riders who spend long days in the saddle. We’ve used a flatter profile, a flexible base and low density foam to create a profile that offers comfort and movement. Features & Benefits of the Scoop Saddle. + Innovative three part construction method. + Flexible base and soft foam cover provide unrivaled comfort. + Available with Cro-mo, titanium or carbon rails. + Suitable for all cycling disciplines. + Multiple “Best in Test” winner. Color: Black w/ Silver. Saddle Cut Out: No. Please ask all questions and do all price shopping before hand. It is not provided for price comparison shopping. For buyers that choose to send offers, please only send offers if you are prepared to pay for the order immediately should the offer be accepted. We do our best to clearly describe all items accurately. Located in Orange County, California – We are a full service retail bicycle boutique specializing in custom builds, particularly Cannondale. We carry all of the hard to find parts and accessories, including all service parts for nearly every Cannondale platform in existence. Don’t see what your looking for? Get in touch and we can most likely help you out.

5 yards 50 Carbon Fiber Fabric Cloth 2×2 Twill Weave (3k, 6oz, 50 x 180)

Twill weave carbon fiber cloth is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality. It has both formability and stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows. Carbon fiber is preferred as it has the highest tensile strength of all reinforcing materials. The dry 3K 2×2 Twill Weave Fabric gives the classic carbon fiber look and conforms to complex parts better than plain weave. It boasts a combined strength and stiffness-to-weight that is unmatched in the composites industry. In fact, when looking at strength to weight comparisons, carbon fiber outperforms most traditional building materials. Carbon fiber can be found everywhere from auto racing to aerospace. Its unmatched strength and weight, along with its modern cosmetics, have made it a widespread favorite in today’s composite industry. Highly desirable for modern composite parts in the aerospace, auto, marine, and sporting goods industries. This is a first quality commercial grade 3K carbon fiber fabric and is made in the USA. 3K means each tow/bundle is constructed of 3000 filaments. The bundles are woven together to form the fabric, which makes it a strong, yet lightweight material. 3K, 563ksi, 34msi, 1.7% elongation. 6 ounces per square yard. When purchasing multiple quantities of the same fabric you will receive one continuous length of that material.

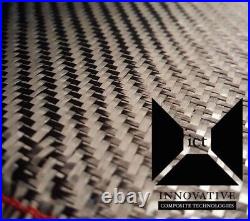

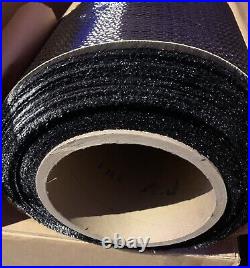

Carbon Fibre Cloth Fabric 240gsm 2/2 3k Twill 1000mm Width, Comes on a Roll UK

240g 2×2 Twill 3k Carbon Fibre Cloth-1000mm width Comes on a roll. 2 x 2 Twill. Hand Laminating / Repair. Carbon Fiber Fabric Twill Weave 240gsm is a high-performance material designed for a wide range of applications, particularly in industries that demand lightweight and exceptionally strong composite materials. The twill weave pattern of this carbon fiber fabric enhances its drapability and conformability, making it an ideal choice for complex shapes and intricate structures. With a weight of 240 grams per square meter (gsm), this fabric strikes a balance between strength and flexibility, making it suitable for aerospace, automotive, and sports equipment manufacturing. The twill weave pattern of this carbon fiber fabric not only contributes to its aesthetic appeal but also imparts superior mechanical properties to the end product. The diagonal pattern enhances the fabric’s strength and impact resistance, making it a preferred choice for applications where structural integrity is critical. The 240gsm weight ensures a sturdy yet lightweight construction, providing the optimal combination of durability and reduced weight. Whether used in aircraft components, automotive parts, or sporting goods, this carbon fiber fabric delivers on both performance and aesthetics. Manufacturers and enthusiasts alike benefit from the exceptional properties of Carbon Fiber Fabric Twill Weave 240gsm. This fabric offers an efficient solution for creating high-strength, lightweight structures, meeting the demands of modern engineering and design. As a key component in composite material production, the carbon fiber fabric twill weave 240gsm continues to play a pivotal role in pushing the boundaries of innovation in diverse applications.

Carbon fiber fabric roll 196GSM/4HS/AS4C GP 3K/1524mm 101 yards Sigmatex Brand

Carbon fiber fabric roll 196GSM/4HS/AS4C GP 3K/1524mm 101 yards Sygmatex Brand.

Next page →