Daily Archives: August 20, 2024

Front & Rear Brake Rotors + Ceramic Pads for 2018 2019 2020 2021 Honda Accord

Honda Accord 2018 – EX – EX – EX-L – EX-L – LX – LX, Honda Accord 2019 – EX – EX – EX-L – EX-L – LX – LX, Honda Accord 2020 – EX – EX – EX-L – EX-L – LX – LX – SE – SE, Honda Accord 2021 – EX-L – EX-L – LX – LX – SE – SE. EX – EX – EX-L – EX-L – LX – LX. EX – EX – EX-L – EX-L – LX – LX – SE – SE. EX-L – EX-L – LX – LX – SE – SE. For your new braking system to operate at its performance capacity, it is important to’break-in’ the rotors and brake pads. This procedure is called bedding and it is encouraged you follow the steps below upon completion of the installation. Find a safe and open area where you will be able to accelerate and stop safely multiple times. Accelerate to 35mph (55km/h) and aggressively stop to 5mph (8km/h) in rapid successions without letting the brakes cool down and without stopping. Repeat this six times. Accelerate to 35mph (55km/h) and this time, moderately stop to 5mph (8km/h) in rapid successions without letting the brakes cool down and without stopping. Drive around for approximately 6-8 minutes at a moderate speed without excessively using the brakes or coming to a complete stop. For Elite XDS & Geomet OE (our coated rotors), and 3 extra minutes. Once this is complete, stop the vehicle and allow the brakes to cool down. This should take about 40 minutes or so. This concludes the bedding procedure and you can now use your brakes normally. However, certain restrictions apply. Note on UPS Extended Area Surcharge: This surcharge is levied by UPS, not Max Advanced Brakes. CT, DE, DC, IL, IN, KY, ME, MD, MA, MI, NH, NJ, NY, NC, OH, PA, RI, SC, TN, VT, VA, WV. AL, AZ, AR, CO, FL, GA, IA, KS, LA, MN, MS, MO, NE, SD, WI. CA, ID, MT, NV, NM, ND, OK, OR, TX, UT, WA, WY. Processing time is subject to change depending on holiday schedule & volume of orders.

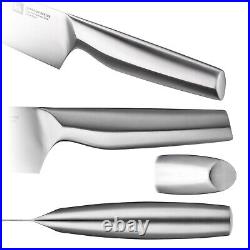

Klaus Meyer Contour Finest high carbon steel 19 Piece Knife Block Set

Contour 19 Piece Set. 8” Chef’s Knife. 5.5” Santoku (Hollow Edge). 4.5” Steak Knife x 8. 3.5” Paring Knife. 1? Finest Stainless Steel Blade Quality. The finest high carbon steel maintains its sharpness over a long period, reducing the need for frequent sharpening. After unique treatment the blade is less prone to chipping and corrosion, maintaining its functionality and appearance. 2? Weight Added Stainless Steel Hollow Handle with Contour Curved Handle. The added weight in the handle provides better balance, making the knife easier to control. A contour curved handle with supremely elegant design enhances grip and comfort, reducing hand strain during extended use. 3? Matte Surface Finish of the Handle. A matte surface on the handle offers a non-slip grip, improving safety and precision in cutting. 4? 53-55 Rockwell Hardness with 15-17 Edge Angle Degree. This level of hardness indicates a good balance between blade flexibility and strength, making it suitable for various cutting tasks. The 15-17 degree edge, deemed as “Golden Angle” of a knife, allows for sharp, precise cuts, enhancing. 5? Oil-Hardened Blades – Exceptional Sharpness and Durability. The process of oil quenching, or oil hardening, is a specialized heat treatment used for these blades. It involves the heating of the knife followed by rapid cooling in oil. This technique offers significant advantages. Reduced Oxidation: By minimizing the blade’s exposure to air during the cooling phase, the process effectively prevents the formation of surface oxidation layers. This enhances the overall quality and lifespan of the blade. Increased Blade Hardness: Oil quenching yields a greater hardness in the steel (by about 1-2HRC) compared to traditional air cooling methods within the same temperature range. Enhanced Toughness and Corrosion Resistance: The oil used in this quenching process forms a protective barrier over the blade. This barrier not only averts oxidation but also improves the blade’s toughness and resistance to rust, surpassing the performance of blades treated with conventional heat methods. The knife’s overall cutting performance. Advantages of this process include preventing prolonged exposure to air, which controls the formation of surface oxidation layers. Oil quenching also results in higher hardness (1-2HRC higher) compared to air cooling in the same temperature range. The oil used in the quenching process covers the blade surface, preventing oxidation and resulting in better toughness and rust resistance compared to conventional heat treatment.