Tag Archives: knife

Next page →

Spyderco Knives Para 3 Sprint Run C223PBN15V Brown FRN CPM 15V Pocket Knife

Made in the U. This Para 3 Liner Lock pocket knife is made of CPM 15V Carbon Steel and Brown FRN Handle. This Sprint Run Spyderco Knives SPYDERCO C223PBN15V, SY C223PBN15V PARA 3 LW BROWN is Big Brown Bear’ Steel Treatment. Para 3 Liner Lock. Big Brown Bear’ Steel Treatment Sprint Run. SKU: SY C223PBN15V PARA 3 LW BROWN. New and never used! CPM 15V Carbon Steel. Handcrafted in the U. SPYDERCO C223PBN15V, SY C223PBN15V PARA 3 LW BROWN/. Whether you’re searching for authentic cutlery to collect, a top quality knife to give as a gift, or a superior blade to carry, don’t pass this one up! This knife utilizes a 3 Locking Skinner blade with a plain edge, full-flat grind, 3.7mm thickness, thumb ramp, spine jimping, and thumb hole. The blade material is CPM 15V Carbon Steel with a Stonewashed finish and’Triple B’ heat treatment. The contoured handle is textured Brown FRN with large lanyard hole and 4-position pocket clip. This magnificent piece is 4 3/8 inches long(closed for folding knives) and weighs approximately 2.4 ounces. Spyderco, founded 1976, initially started as a’knife sharpener’ company, but ultimately revolutionized the entire knife industry. They realized the need for a new type of pocket knife. A high-quality locking blade that could be carried at the top of the pocket, opened easily with one-hand, and could provide superior hand control. The combination of these features has since given rise to what we now consider the modern folding knife. Spyderco’s innovation, choice of materials, and attention to detail have made them a world-class brand. You can’t have a quality knife without a quality to go with it. Produced by Spyderco Knives. And made in the U. This was developed with the true knife enthusiast in mind. It is and made of well-crafted. We’ve made some changes to our Ads… Authorized Dealer.

Kansept Knives BTF Linerlock Green Carbon Fiber Folding CPM-S35VN Knife 1064A2

Kansept Knives BTF Linerlock Green Carbon Fiber Folding CPM-S35VN Knife 1064A2. 3.24” Black stonewashed finish CPM-S35VN steel tanto blade. Grass green and black carbon fiber handle. Tip-Up right carry pocket clip. Designed by Rolf Helbig. Auctiva Offers Free Image Hosting and Editing. Track Page Views With. Auctiva’s FREE Counter.

Case XX 50629 Welker Rw Caper Fixed Knife Tan Micarta Carbon Steel & Sheath

CASE XX 50629 WELKER RW CAPER FIXED BLADE KNIFE – 1095 CARBON STEEL DROP POINT BLADE – NATURAL TAN MICARTA HANDLE – GENUINE LEATHER SHEATH – PATTERN STAMP RW CAPER 1095 CS USA. BRAND NEW IN BOX. Pattern Stamp: RW CAPER 095 CS USA. Blade Length: 4 1/8. Handle Length: 4 1/2. Overall Length: 8 5/8. Blade Style: Drop Point. Blade Material: 1095 Carbon Steel with a Stonewash Finish. Handle Material: Natural Tan Micarta. Sheath: Genuine Fitted Leather. Approximate Weight: 6.25 oz. ITEMS MUST BE PAID FOR AT THE SAME TIME TO QUALIFY FOR ANY DISCOUNT. NOTE: IT IS THE RESPONSIBILITY OF THE PURCHASER TO ABIDE BY ALL LOCAL, STATE, AND FEDERAL LAWS. OUR GOAL IS TO SATISFY EVERY CUSTOMER. WE CANNOT RESOLVE AN ISSUE IF WE ARE NOT AWARE OF IT. Don’t let our low prices fool you! All of our merchandise is New and First quality unless otherwise stated. At TheKnifeCellar, the customer always comes first!

Spartan Blades Nemec Folding Knife 3.5 S35VN Steel Blade Carbon Fiber Handle

Nemec Linerlock Carbon Fiber. 4.5 (11.43cm) closed. 3.5 (8.89cm) black stonewash finish S35VN stainless blade. The discounts are based on the packages weight. Also, please, investigate your local laws before placing an order from us as many items we sell (like some knife models) despite of being legal here in the United States, are prohibited in some countries. At Survivor Hand, we are committed to providing our customers with the best possible on-line shopping experience. This includes a commitment to excellent customer service, even after your order has been delivered. You questions will be answered in, as much, 12 hours. And in many cases during the daytime, you may receive an answer in minutes. Track Page Views With. Auctiva’s FREE Counter.

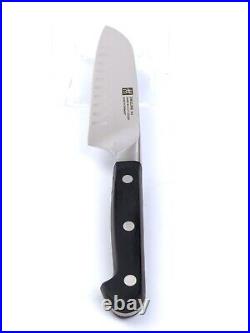

Zwilling PRO 38408-140 5.5 in SANTOKU Knife, Made in GERMANY, Carbon Steel, NEW

Zwilling PRO 38401-200 5.5-inch SANTOKU Knife w/ Curved Bolster & Full-Edge Utility. Blade Material: Special Stain Resistant Formula Carbon Steel, FRIODUR Ice Hardened. Manufactured: Made in GERMANY. Condition: NEW, Never Used! Need a Knife Block to go along with your new Knife? I have all sizes, brands, and finishes available! Check out my store OneOfAKindCustomCollectibles.

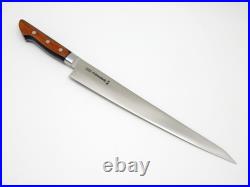

Yoshihiro Hi-Carbon Japan Steel(SK-4), HGB Series Japanese Chef’s Sujihiki Knife

Yoshihiro/High Carbon Japan Steel(Forged SK-4 Steel), HGB Series Japanese Chef’s Sujibiki Knife Slicer, manufactured by one of the most famous workshop, Yoshihiro Cutlery Mfg. Taking advantage of Forged SK-4 with sustainable sharpness, these knives are manufactured, one by one, with special quenching & grinding technique in a traditional way, here in Sakai, which can achieve to be easy to resharpen with high durability. These knives get rust in wet condition, but ferrous oxide(Fe203) is harmless to human body. HGB has a variety of Blade type;Chef’s Knife(Gyuto), Paring Knife, Sujibiki(Slicer), Sabaki(Boning), etc. Yoshihiro Hi-Carbon Japan Steel(SK-4), HGB Series Japanese Chef’s Sujihiki Knife. High Carbon Japan Steel(Forged SK-4 Steel), HGB Series Japanese Chef’s Sujibiki Knife Slicer. Manufactured by one of the most famous workshop. With sustainable sharpness, these knives are manufactured, one by one, with special quenching & grinding technique in a traditional way, here in Sakai, which can achieve to be easy to resharpen with high durability. HGB has a variety of Blade type. Chef’s Knife(Gyuto), Paring Knife, Sujibiki(Slicer), Sabaki(Boning), etc. Main photo images show 270S:270 mm/10.6 model for your reference. Yoshihiro(Goh Umanosuke Yoshihiro). High Carbon Japan Steel(Forged SK-4). Blade Length (Total Length). 240S:240 mm/9.3″(360 mm/14.2″) 270S:270 mm/10.6″ (395 mm/15.6″). Wooden Saya Cover & Ebony Saya Pin, originally stamped by Yoshihiro See variation(Select Saya Cover, Included). Blade Length of the Knife defines the length from top edge of the blade to the end, Not at the root of steel. From Monday to Friday. Normally 5 – 7 days. Yen 6,000. Normally 1 – 2 weeks. International Buyers – Please note. YuiSenri, based in Sakai City/Osaka, has been Japanese Knife Shop since 2011, focusing on Hand-made by skillful artisans. We are the authorized distibutor of “Sakai Takumi Ajimasa”, “Yoshihiro”, “Sakai Takayuki” & “Sakai Kikumori”, leading cutlery workshops in Sakai City, Osaka. Visit our Shop NOW!!! Our Shop opens from Monday to Friday (9:00 – 18:00) except National Holiday and New Year Holiday. We usually reply to you about new inquiries or questions within 24 hours. If you have any question, pricing or terms & conditions, please feel free to ask us. Get more from our shop, YuiSenri! Thank you very much for visiting us! Enjoy Shopping and experience Japanese style! Auctiva offers Free Image Hosting and Editing. Auctiva gets you noticed! Track Page Views With.

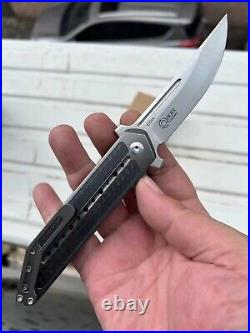

Titanium alloy carbon fiber bearing fast opening EDC knife S35VN blade material

Total length: 21.5cm. Handle length: 12.3cm. Handle material: Carbon fiber +TC4 titanium alloy CNC. Blade length: 9.1cm. Blade thickness: 0.4mm. Blade width: 2.2mm. Hardness: 60-61HRC (vacuum oil quenching heat treatment + tempering 2 times). Back clip: TC4 titanium alloy. Weight: 192g (including packaging). Packing: Gift box screw: all screws 420 stainless steel hardness HRC45, full CNC precision machining, built-in bearing ball system. PS: The product is sharp, please keep away from children.

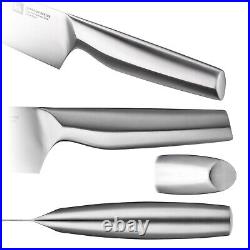

Klaus Meyer Contour Finest high carbon steel 19 Piece Knife Block Set

Contour 19 Piece Set. 8” Chef’s Knife. 5.5” Santoku (Hollow Edge). 4.5” Steak Knife x 8. 3.5” Paring Knife. 1? Finest Stainless Steel Blade Quality. The finest high carbon steel maintains its sharpness over a long period, reducing the need for frequent sharpening. After unique treatment the blade is less prone to chipping and corrosion, maintaining its functionality and appearance. 2? Weight Added Stainless Steel Hollow Handle with Contour Curved Handle. The added weight in the handle provides better balance, making the knife easier to control. A contour curved handle with supremely elegant design enhances grip and comfort, reducing hand strain during extended use. 3? Matte Surface Finish of the Handle. A matte surface on the handle offers a non-slip grip, improving safety and precision in cutting. 4? 53-55 Rockwell Hardness with 15-17 Edge Angle Degree. This level of hardness indicates a good balance between blade flexibility and strength, making it suitable for various cutting tasks. The 15-17 degree edge, deemed as “Golden Angle” of a knife, allows for sharp, precise cuts, enhancing. 5? Oil-Hardened Blades – Exceptional Sharpness and Durability. The process of oil quenching, or oil hardening, is a specialized heat treatment used for these blades. It involves the heating of the knife followed by rapid cooling in oil. This technique offers significant advantages. Reduced Oxidation: By minimizing the blade’s exposure to air during the cooling phase, the process effectively prevents the formation of surface oxidation layers. This enhances the overall quality and lifespan of the blade. Increased Blade Hardness: Oil quenching yields a greater hardness in the steel (by about 1-2HRC) compared to traditional air cooling methods within the same temperature range. Enhanced Toughness and Corrosion Resistance: The oil used in this quenching process forms a protective barrier over the blade. This barrier not only averts oxidation but also improves the blade’s toughness and resistance to rust, surpassing the performance of blades treated with conventional heat methods. The knife’s overall cutting performance. Advantages of this process include preventing prolonged exposure to air, which controls the formation of surface oxidation layers. Oil quenching also results in higher hardness (1-2HRC higher) compared to air cooling in the same temperature range. The oil used in the quenching process covers the blade surface, preventing oxidation and resulting in better toughness and rust resistance compared to conventional heat treatment.

Klaus Meyer Stahl High Carbon Steel 19 Piece Knife Block Set

Stahl 19 Piece Set. 8” Chef’s Knife. 5.5” Santoku (Hollow Edge). 4.5” Steak Knife x 8. 3.5” Paring Knife. 1? Stahl series knife set block is an essential and stylish addition to any kitchen, combining functionality, safety, and aesthetic appeal with a variety of knives including all-purpose knives and task knives. 2? Crafted from high-quality 5Cr15Mov high carbon stainless steel, ensuring durability, long-lasting sharpness (54-56HRC), and rust resistance. The blades are precision-engineered for optimal cutting performance. 3? Oil-quenched process makes these knives even harder and more durable regarding anti-corrosion than others of similar material. 4? German-Engineered triple rivets ABS handle promise stability and longevity while providing comfortable grip of the knives.

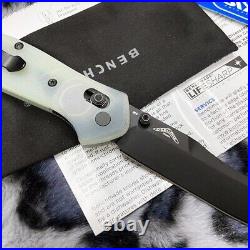

AXIS New Benchmade Jade Handle G-10 Black Osborne Folding Knife 940BK-2004

AXIS New Benchmade Jade Handle G-10 Black Osborne Folding Knife 940BK-2004. The Benchmade 940 Osborne has become a classic in the knife industry. Just about every knife enthusiast is familiar with it. A few years back, Blade HQ took a poll and the community placed the 940 Osborne among the five knives everyone should own. Its tough build, slim profile, and versatile design makes it a perfect tool for every Benchmade knife aficionado. Overall Length:7.87. Blade Length:3.40. Blade Thickness:0.12. Blade Material:CPM M4. Blade Style:Reverse Tanto. Handle Length:4.47. Handle Thickness:0.44. Weight:2.65 oz. User:Right Hand, Left Hand. Lock Type:Crossbar Lock. Country of Origin:USA. Best Use:Camp/Hike, Everyday Carry. Premium CPM M4 blade steel holds a great edge and will resist abuse. Jade G-10 handle is translucent, showing off the inner workings. Benchmade Axis lock for ambidextrous use with dual thumb studs. Classic Warren Osborne design made for long-lasting and efficient cuts and slices. Reversible pocket clip for right or left side carry. Please feel free to contact me with any questions.

Next page →