Tag Archives: film

Next page →

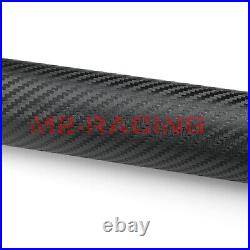

Carbon Fiber Film Glossy Black Car Body Film Forged Carbon Fiber Vinyl Wrap Film

Forged Carbon Fiber Film. Car Body protective film. Sticker for Rearview mirror. Adhesive vinyl for car. Glossy brushed carbon film.

Carbon Fibre Vinyl Wrap Forged Carbon Black Matte Sheet Film Bubble Free UK

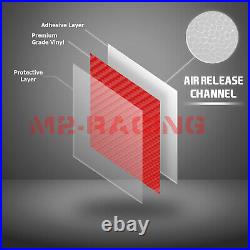

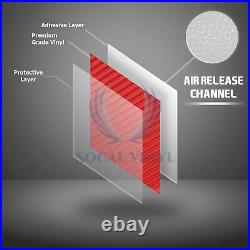

Carbon fibre forged look vinyl car wraps offer a sleek and dynamic aesthetic upgrade for vehicles, transforming their appearance with a striking resemblance to genuine carbon fiber. The allure lies in the meticulous detailing that mimics the texture and depth of carbon fiber weave, delivering a high-end finish without the exorbitant cost associated with authentic carbon fiber components. With its lightweight and flexible properties, vinyl wrap seamlessly conforms to the curves and contours of any vehicle, ensuring a smooth and flawless application. Whether adorning the hood, roof, or even the entire body, this wrap adds a touch of sportiness and sophistication, elevating the car’s visual appeal to new heights. Beyond its aesthetic appeal, carbon fibre forged look vinyl wraps offer practical benefits for car owners. The vinyl material provides a layer of protection against scratches, chips, and UV damage, preserving the underlying paintwork and maintaining the vehicle’s resale value. Moreover, the wrap’s durability ensures longevity, allowing the car to maintain its freshly styled appearance for years to come with minimal maintenance. Available in a variety of colors, finishes, and textures, car enthusiasts can personalize their vehicles to reflect their unique style and personality. Whether opting for a glossy finish to enhance the illusion of depth or a matte finish for a more understated elegance, the versatility of vinyl wraps allows for endless customization possibilities. From sleek sports cars to rugged off-road vehicles, this transformative solution enables drivers to make a statement on the road, turning heads and setting trends wherever they go. Applying a carbon fibre forged look vinyl car wrap requires precision, patience, and attention to detail. Before starting, ensure the vehicle’s surface is clean, smooth, and free of any contaminants or imperfections that could affect adhesion. Begin by carefully measuring and cutting the vinyl wrap to fit each panel of the car, leaving a slight overhang to ensure complete coverage. Using a heat gun, gently warm the vinyl to increase pliability, making it easier to stretch and conform around curves and edges. Then, starting from one edge, gradually smooth the vinyl onto the surface, using a squeegee to remove any air bubbles and ensure a seamless finish. Pay close attention to corners and recessed areas, using the heat gun to soften the vinyl and facilitate adhesion. Once applied, trim any excess material and use a heat gun to activate the adhesive, ensuring a secure bond. Finally, give the wrap a thorough inspection to ensure proper alignment and adhesion, making any necessary adjustments before enjoying the newly transformed look of the vehicle. Bout e carbon fibre fabric for a truly eye-catching part! Race Cars & Automotive. Black Forged Carbon Pattern. Carbon Fibre Forged Pattern Vinyl. Applying vinyl wrap to a vehicle or other surfaces involves several detailed steps to ensure a smooth, professional finish. Here’s a comprehensive guide to help you through the process. Wash the vehicle or object thoroughly to remove dirt, grease, and other contaminants. Use a gentle car wash soap and water. Once dry, wipe the surface with isopropyl alcohol to ensure all residues are removed. This step is crucial for proper adhesion. Remove or mask off any parts that could obstruct the wrapping process, such as emblems, mirrors, and door handles. This allows for a seamless application. Measure the surface area to determine how much vinyl wrap you need. Cut the vinyl wrap into manageable pieces, adding a few extra inches to each side to allow for adjustments. Start by peeling back a small portion of the backing paper from the vinyl wrap. Align the exposed section of the vinyl with the area you are covering and tack it down lightly. Gradually peel away the backing paper while smoothing the vinyl onto the surface with a squeegee. Use firm, overlapping strokes to press the vinyl onto the surface, working from the center outward to avoid air bubbles and wrinkles. Use a heat gun to gently warm the vinyl, making it more pliable and easier to stretch over curves and contours. Carefully stretch and smooth the vinyl over complex shapes, using the squeegee to press out air bubbles and ensure a tight fit. Once the vinyl is applied, use a sharp utility knife to trim any excess material around the edges. Be precise and careful to avoid cutting into the vehicle’s paint or the surface underneath. Use the heat gun to warm the entire surface of the vinyl wrap once more. This helps set the adhesive and ensures long-lasting adhesion. Focus extra heat on edges and seams to secure them firmly. Check the entire surface for any remaining air bubbles or imperfections. If you find any, use a pin to pop the bubbles and smooth them out with the squeegee. Reattach any parts you removed or masked off earlier, such as mirrors or emblems. By following these steps, you can achieve a professional-quality vinyl wrap application, transforming the appearance of your vehicle or any other surface with a sleek, customized finish. Vinyl wrap with air channels and a top clear protective layer represents a sophisticated advancement in wrapping technology, designed to facilitate a smoother and more durable application process. Here’s a detailed description of this type of vinyl wrap. Vinyl wraps with air channel technology incorporate tiny, invisible channels into the adhesive layer. These channels allow air to escape as the wrap is applied, preventing bubbles from forming. This feature significantly simplifies the application process, making it easier for both professionals and DIY enthusiasts to achieve a flawless finish. The air channels enable the installer to reposition the vinyl multiple times during the application, ensuring perfect alignment before final adhesion. This technology reduces the likelihood of wrinkles and other imperfections, providing a smooth, uniform appearance across the entire surface. Top Clear Protective Layer. The top clear protective layer acts as a shield against environmental factors such as UV rays, dirt, and minor abrasions. This helps maintain the vinyl’s vibrant color and glossy finish over time. It adds an extra layer of protection to the vehicle’s original paint, preventing potential damage and extending the lifespan of both the wrap and the underlying surface. The protective layer makes cleaning and maintaining the vinyl wrap straightforward. The smooth surface can be easily wiped down with mild soap and water, keeping the wrap looking pristine with minimal effort. It also resists stains and discoloration, ensuring the wrap remains visually appealing even after prolonged exposure to the elements. Combining air channel technology with a top clear protective layer provides a high-quality, professional-grade finish that rivals traditional paint jobs. This type of vinyl wrap is ideal for both personal and commercial applications, offering a cost-effective and versatile solution for vehicle customization and surface protection. The advanced features of these vinyl wraps make them suitable for a wide range of surfaces, including cars, motorcycles, boats, and even interior design elements like furniture and appliances. The easy application and durable finish make it a popular choice for temporary branding or long-term aesthetic transformations. By incorporating these advanced features, vinyl wraps with air channels and a top clear protective layer deliver an exceptional combination of ease of use, durability, and visual appeal, making them an excellent choice for various wrapping projects. We don’t accept address change after an order, you will have to re order with the correct address. & Public holiday excluded.

3D Carbon Fiber Black Matte Textured Car Vinyl Wrap Sticker Decal Film Sheet DIY

3D Carbon Fiber Black Matte Textured Car Vinyl Wrap Sticker Decal Film Sheet DIY. Automotive Vinyl Wrap Film. Gloss / Gloss Metallic. Matte / Satin / Matte Metallic. Leather / Suede / Velvet. One Way Vision Privacy. Wrapping & Tinting Tools. Free Tool Kit Requirement. Come with Tool Kit. Size of 12″x60″ Include 1 set of Basic Tool Kit. Size of 24″x60″ and above Include 1 set of Deluxe Tool Kit. Thickness of film (C=10 micron): 15C±0.5C. Thickness of film with release liner: 31C±0.5C. Type of film: Hybrid vinyl film with air channels (Designed for vehicle exterior with prefect paint condition). Glue: Solvent based adhesive, odor: solvent odor (Low-Medium Tack – Easy to reposition). Release liner: White silicone-coated paper with double-sided polyethylene coating, small square air release channels, origin Germany. Storing period: 2 years if stored in +10°? To +20°? For optimal quality, relative humidity 50%, in original package, away from direct sun light, clean and dry place. Indoor life: 4 years when followed rules of application and use. Outdoor life: 3 years when followed rules of application and use. Application: from +10°? To +20°? , usage from -30°? To +30°? Dimensional stability: shrinkage less than 5%. Breaking Strength: 22.7 N/10mm (Average). Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average). Test Method: ASTM D3330/D3330-04. Light Ageing in UV Exposure. Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor. Exposure cycle: ASTM D4329-13 cycle A. Lamp type: UVA-3408h UV at (60±2.5). Water resistant and weather proof. Flexible and Stretchable for concave area. Low cost to change the look of your vehicles. Easy installation with dry application method. Heat gun or household blow dryer for shaping is required. Low – medium tack self adhesive (Easy to Reposition). Easy to fit in most tight spots or corners (primer 94 is required for non sticky surfaces, curves & corners). Fluorescent Neon colors tend to fade faster than normal colors. Fading can be reduced with over lamination, preventing stretched areas, which fade even faster, and shelter from high U. Times during the day. Material is specially made for vehicle exterior paint surface in good condition. Buyers take self responsibility on unsuccessful result on other usage. Always pre-test vinyl installation on vehicles. Due to different monitors/calibrations, colors may vary slightly from the pictures. Film colors can vary slightly from roll to roll. For best result, professional installation is required; Buyers take responsibility on physical damage during installation such as over heating, over stretching, ripping. This vinyl is designed for vehicle exterior wrap use ONLY. This vinyl won’t stick good on polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, plastic, textured, aluminum, metal. Installers must use primer 94 for additional adhesion. This vinyl is not originally designed for plotter or cutter use. We would try our best to help you solving any problem. We are trying our best to describe all details of the product here. We will try our best to solve the problem with you. We appreciate your business.

18 Colors 3D Matte Carbon Fiber Vinyl Sticker Wrap Decal Sheet Film DIY Decal

3D Matte Dry Carbon Fiber Vinyl Sticker Wrap Decal Sheet Film DIY. Automotive Vinyl Wrap Film. Gloss / Gloss Metallic. Matte / Satin / Matte Metallic. Leather / Suede / Velvet. One Way Vision Privacy. Wrapping & Tinting Tools. Free Tool Kit Requirement. Come with Tool Kit. Size of 12″x60″ Include 1 set of Basic Tool Kit. Size of 24″x60″ and above Include 1 set of Deluxe Tool Kit. Thickness of film (C=10 micron): 15C±0.5C. Thickness of film with release liner: 31C±0.5C. Type of film: Hybrid vinyl film with air channels (Designed for vehicle exterior with prefect paint condition). Glue: Solvent based adhesive, odor: solvent odor (Low-Medium Tack – Easy to reposition). Release liner: White silicone-coated paper with double-sided polyethylene coating, small square air release channels, origin Germany. Storing period: 2 years if stored in +10°? To +20°? For optimal quality, relative humidity 50%, in original package, away from direct sun light, clean and dry place. Indoor life: 4 years when followed rules of application and use. Outdoor life: 3 years when followed rules of application and use. Application: from +10°? To +20°? , usage from -30°? To +30°? Dimensional stability: shrinkage less than 5%. Breaking Strength: 22.7 N/10mm (Average). Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average). Test Method: ASTM D3330/D3330-04. Light Ageing in UV Exposure. Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor. Exposure cycle: ASTM D4329-13 cycle A. Lamp type: UVA-3408h UV at (60±2.5). Water resistant and weather proof. Flexible and Stretchable for concave area. Low cost to change the look of your vehicles. Easy installation with dry application method. Heat gun or household blow dryer for shaping is required. Low – medium tack self adhesive (Easy to Reposition). Easy to fit in most tight spots or corners (primer 94 is required for non sticky surfaces, curves & corners). Fluorescent Neon colors tend to fade faster than normal colors. Fading can be reduced with over lamination, preventing stretched areas, which fade even faster, and shelter from high U. Times during the day. Material is specially made for vehicle exterior paint surface in good condition. Buyers take self responsibility on unsuccessful result on other usage. Always pre-test vinyl installation on vehicles. Due to different monitors/calibrations, colors may vary slightly from the pictures. Film colors can vary slightly from roll to roll. For best result, professional installation is required; Buyers take responsibility on physical damage during installation such as over heating, over stretching, ripping. This vinyl is designed for vehicle exterior wrap use ONLY. This vinyl won’t stick good on polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, plastic, textured, aluminum, metal. Installers must use primer 94 for additional adhesion. This vinyl is not originally designed for plotter or cutter use. We would try our best to help you solving any problem. We are trying our best to describe all details of the product here. We will try our best to solve the problem with you. We appreciate your business.

5D Carbon Fiber Black High Gloss Glossy Auto Vinyl Wrap Sticker Decal Sheet Film

5D Carbon Fiber Black High Gloss Glossy Auto Vinyl Wrap Sticker Decal Sheet Film. Automotive Vinyl Wrap Film. Gloss / Gloss Metallic. Matte / Satin / Matte Metallic. Leather / Suede / Velvet. One Way Vision Privacy. Wrapping & Tinting Tools. Free Tool Kit Requirement. Come with Tool Kit. Size of 12″x60″ Include 1 set of Basic Tool Kit. Size of 24″x60″ and above Include 1 set of Deluxe Tool Kit. Thickness of film (C=10 micron): 15C±0.5C. Thickness of film with release liner: 31C±0.5C. Type of film: Hybrid vinyl film with air channels (Designed for vehicle exterior with prefect paint condition). Glue: Solvent based adhesive, odor: solvent odor (Low-Medium Tack – Easy to reposition). Release liner: White silicone-coated paper with double-sided polyethylene coating, small square air release channels, origin Germany. Storing period: 2 years if stored in +10°? To +20°? For optimal quality, relative humidity 50%, in original package, away from direct sun light, clean and dry place. Indoor life: 4 years when followed rules of application and use. Outdoor life: 3 years when followed rules of application and use. Application: from +10°? To +20°? , usage from -30°? To +30°? Dimensional stability: shrinkage less than 5%. Breaking Strength: 22.7 N/10mm (Average). Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average). Test Method: ASTM D3330/D3330-04. Light Ageing in UV Exposure. Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor. Exposure cycle: ASTM D4329-13 cycle A. Lamp type: UVA-3408h UV at (60±2.5). Water resistant and weather proof. Flexible and Stretchable for concave area. Low cost to change the look of your vehicles. Easy installation with dry application method. Heat gun or household blow dryer for shaping is required. Low – medium tack self adhesive (Easy to Reposition). Easy to fit in most tight spots or corners (primer 94 is required for non sticky surfaces, curves & corners). Fluorescent Neon colors tend to fade faster than normal colors. Fading can be reduced with over lamination, preventing stretched areas, which fade even faster, and shelter from high U. Times during the day. Material is specially made for vehicle exterior paint surface in good condition. Buyers take self responsibility on unsuccessful result on other usage. Always pre-test vinyl installation on vehicles. Due to different monitors/calibrations, colors may vary slightly from the pictures. Film colors can vary slightly from roll to roll. For best result, professional installation is required; Buyers take responsibility on physical damage during installation such as over heating, over stretching, ripping. This vinyl is designed for vehicle exterior wrap use ONLY. This vinyl won’t stick good on polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, plastic, textured, aluminum, metal. Installers must use primer 94 for additional adhesion. This vinyl is not originally designed for plotter or cutter use. We would try our best to help you solving any problem. We are trying our best to describe all details of the product here. We will try our best to solve the problem with you. We appreciate your business.

3D Carbon Fiber Black Matte Textured Car Vinyl Wrap Sticker Decal Film Sheet DIY

3D Carbon Fiber Black Matte Textured Car Vinyl Wrap Sticker Decal Film Sheet DIY. Free Tool Kit Requirement. Come with Tool Kit. Size of 12″x60″ Include 1 set of Basic Tool Kit. Size of 24″x60″ and above Include 1 set of Deluxe Tool Kit. Thickness of film (C=10 micron): 15C±0.5C. Thickness of film with release liner: 31C±0.5C. Type of film: Hybrid vinyl film with air channels (Designed for vehicle exterior with prefect paint condition). Glue: Solvent based adhesive, odor: solvent odor (Low-Medium Tack – Easy to reposition). Release liner: White silicone-coated paper with double-sided polyethylene coating, small square air release channels, origin Germany. Storing period: 2 years if stored in +10°? To +20°? For optimal quality, relative humidity 50%, in original package, away from direct sun light, clean and dry place. Indoor life: 4 years when followed rules of application and use. Outdoor life: 3 years when followed rules of application and use. Application: from +10°? To +20°? , usage from -30°? To +30°? Dimensional stability: shrinkage less than 5%. Breaking Strength: 22.7 N/10mm (Average). Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average). Test Method: ASTM D3330/D3330-04. Light Ageing in UV Exposure. Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor. Exposure cycle: ASTM D4329-13 cycle A. Lamp type: UVA-3408h UV at (60±2.5). Water resistant and weather proof. Flexible and Stretchable for concave area. Low cost to change the look of your vehicles. Easy installation with dry application method. Heat gun or household blow dryer for shaping is required. Low – medium tack self adhesive (Easy to Reposition). Easy to fit in most tight spots or corners (primer 94 is required for non sticky surfaces, curves & corners). Fluorescent Neon colors tend to fade faster than normal colors. Fading can be reduced with over lamination, preventing stretched areas, which fade even faster, and shelter from high U. Times during the day. Material is specially made for vehicle exterior paint surface in good condition. Buyers take self responsibility on unsuccessful result on other usage. Always pre-test vinyl installation on vehicles. Due to different monitors/calibrations, colors may vary slightly from the pictures. Film colors can vary slightly from roll to roll. For best result, professional installation is required; Buyers take responsibility on physical damage during installation such as over heating, over stretching, ripping. This vinyl is designed for vehicle exterior wrap use ONLY. This vinyl won’t stick good on polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, plastic, textured, aluminum, metal. Installers must use primer 94 for additional adhesion. This vinyl is not originally designed for plotter or cutter use. We do have many other items available!!! We would try our best to help you solving any problem. We are trying our best to describe all details of the product here. We will try our best to solve the problem with you. We appreciate your business.

DIY Adhesive Black 4D Texture Carbon Fiber Vinyl Tape Wrap Sticker Film Decal AB

US Local Goods – FAST. Super Glossy Glitter Film. Glossy Car Paint Wrap. Hot Vinyl & Size. Satin Matte Chrome -? New? Chrome Mirror -? Hot? Chrome 3D Carbon Fiber. 2D 3D 4D 5D Carbon Fiber. Chameleon 3D / Glossy. Flat Matte Finish Vinyl. High Glossy Paint – Black. 12″ x 50″ & 12″ x 60″. 24″ x 48″ / 0.6M x 1.2M. Optional? Samples? All Vinyl. Carbon Fiber Series. Chrome Mirror / 3D / 4D. Flash Glitter Series. Matte Finish Series. Special Effect Vinyl. Headlight Tint Film. General Headlight Tint. Wholesale / Full Roll. 2D / 3D Wrap. All in 1 Listing. 60 W? 3D Carbon Fiber II. 50 W? 3D Carbon Fiber I. 50 W? 2D? High Glossy? All Size & Colour. One Size / Easy. Thickness? – 40C / 0.4mm Best! Flashy Glitter Film. Invisible Car Cloth. Width:? 4 / 10cm? Width:? 6 / 15cm? Width:? 8 / 20cm? Width:? 60 / 150cm? – Car Wrap. Width:? 30 / 75cm? Matte Finish Wrap. Metallic Brushed Film. Glossy Paint Tape. Satin Metal Tape. Brushed Chrome Tape. DIY Adhesive Black 4D Texture Carbon Fiber Vinyl Tape Wrap Sticker Film Decal AB. The picture is just an effect, according to the size you ordered pls. Design: Multi-Function 4D Black Tape. Material: High PVC film. Outdoor durability: around 5 years. More than 10 Years. Heat temperature: More than +180 degree. Temperature resistance: From -30 degree to + 250 degree. Wide Used for decoration. You choose the width and length and quantity. The system will automatically open unpaid item case after 7 days. Pls feel free to write to. Us when you meet any problem. Epend on the weight of the parcels, if you bought more than 1 items, we will combine them. For you, and it will be safe. When you want to return the item, pls do a good packaging to make it. Arrive in good condition for resell, thank you =.

5D Carbon Fiber Black High Gloss Glossy Auto Vinyl Wrap Sticker Decal Sheet Film

5D Carbon Fiber Black High Gloss Glossy Auto Vinyl Wrap Sticker Decal Sheet Film. Heat Transfer Vinyl (HTV). Glow in the Dark. One Way Vision (OWV). Auto Parts & Accessories. Mirror & Mirror Cover. Steering Wheel & Cover. Door Guard & Trim. Paint Protection Film (PPF). Free Tool Kit Requirement. Come with Tool Kit. Size of 12″x60″ Include 1 set of Basic Tool Kit. Size of 24″x60″ and above Include 1 set of Deluxe Tool Kit. Thickness of film (C=10 micron): 15C±0.5C. Thickness of film with release liner: 31C±0.5C. Type of film: Hybrid vinyl film with air channels (Designed for vehicle exterior with prefect paint condition). Glue: Solvent based adhesive, odor: solvent odor (Low-Medium Tack – Easy to reposition). Release liner: White silicone-coated paper with double-sided polyethylene coating, small square air release channels, origin Germany. Storing period: 2 years if stored in +10°? To +20°? For optimal quality, relative humidity 50%, in original package, away from direct sun light, clean and dry place. Indoor life: 4 years when followed rules of application and use. Outdoor life: 3 years when followed rules of application and use. Application: from +10°? To +20°? , usage from -30°? To +30°? Dimensional stability: shrinkage less than 5%. Breaking Strength: 22.7 N/10mm (Average). Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average). Test Method: ASTM D3330/D3330-04. Light Ageing in UV Exposure. Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor. Exposure cycle: ASTM D4329-13 cycle A. Lamp type: UVA-3408h UV at (60±2.5). Water resistant and weather proof. Flexible and Stretchable for concave area. Low cost to change the look of your vehicles. Easy installation with dry application method. Heat gun or household blow dryer for shaping is required. Low – medium tack self adhesive (Easy to Reposition). Easy to fit in most tight spots or corners (primer 94 is required for non sticky surfaces, curves & corners). Fluorescent Neon colors tend to fade faster than normal colors. Fading can be reduced with over lamination, preventing stretched areas, which fade even faster, and shelter from high U. Times during the day. Material is specially made for vehicle exterior paint surface in good condition. Buyers take self responsibility on unsuccessful result on other usage. Always pre-test vinyl installation on vehicles. Due to different monitors/calibrations, colors may vary slightly from the pictures. Film colors can vary slightly from roll to roll. For best result, professional installation is required; Buyers take responsibility on physical damage during installation such as over heating, over stretching, ripping. This vinyl is designed for vehicle exterior wrap use ONLY. This vinyl won’t stick good on polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, plastic, textured, aluminum, metal. Installers must use primer 94 for additional adhesion. This vinyl is not originally designed for plotter or cutter use. We would try our best to help you solving any problem. We are trying our best to describe all details of the product here. We will try our best to solve the problem with you. We appreciate your business.

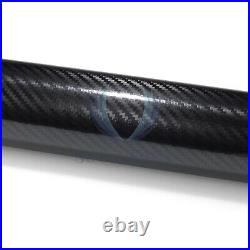

Black 5D Carbon Fibre Vinyl Wrap Sheet Film Sticker Car Wrap Air Bubble Free

Available length of roll up to 30 Meters. Not only does it look stylish but is more flexible and is a certified automotive wrap vinyl unlike 3M DI-NOC which is a interior design film. Our wrap vinyl is a must have for full wraps. Can be applied to Your cars hood, Boot, roof, dashboard, gauges, interior, amplifiers, wheels, mirrors, door handles, glass, cell phones, laptops, iPods, motorcycle parts, metal parts and just about any relatively non-porous surface. The film is coated with a UV coating, Once applied and bonded to your surface you may clean it with any type of cleaning agent that is used for painted surfaces. The material is soft and highly flexible allowing it to conform to contours and bend easily. After applying the Vinyl Sheet, you simply trim the excess vinyl with a sharp blade or hobby knife (not included). What you have left is a customized look without the headaches and costs associated with spraying. O Made with automotive grade premium high quality cast vinyl that is used for wraps and conforms to the most challenging contours and shapes, Can be re lifted, repositioned and stretched before going over with a squeegee. When applied correctly to the appropriate hard surface the film is very durable. O Any creases/folds will come out with heating from haidryer or heat gun, Will not harm painted surfaces. Can be easily repositioned during installation and does not leave adhesive residue behind, Grid pattern backing for more precise measuring and cutting. O Top quality German adhesive with built-in air channels for easy, bubble-free installation Extremely Flexible and can be applied to moderate curves or any smooth flat surface. O Coated with a UV protective layer, Durable material resistant to water, dirt, grease, salt, mild acid and oil Easily remove without residue, will not harm the painted surface of your vehicle. O Extra Wide Avaliable for cover of roofs, bonnets etc. O Strong self-adhesive sticker can be applied to virtually any surface. O High temperture resistant (-30 to +150c) UV protected. O Durability: indoor 8-10 years outdoor 5-7 years. O Easly Removed Without leaving glue behind. O Stretchable with heat from hairdryer or heatgun. O Thickness 0.20mm.

3D Matte Carbon Fiber Vinyl Wrap Film Wrap Roll Bubble Free Air Release Decal

Self-adhesive, peel and stick. Will not fade, chip, crack nor peel. This vinyl film is Universal fit it will fit any cars SUVs etc. Please make sure the size is enough for your vehicle, simply clean the surface and apply this vinyl film sheet to any smooth surface and cut off the edge. It will not damage your surface nor leave any residual later when you remove this. There may be some air bubbles between the vinyl sheet and the protective film that look like “damage”, however once the protective film is peeled off the actual vinyl sheet will be just fine.

Next page →